Bluefin tuna – an iconic example for recovery

Bluefin tuna is known for its size and price. A new management strategy is to ensure the long-term sustainable management of the stocks in the Atlantic.

After four years of absence, it was high time to assess the progress in the Japanese fish and seafood industry. At breeding stations, aquacultures, processing plants, cold storage facilities, and specific fish restaurants, we gathered numerous impressions to understand the business models more profoundly. We established new contacts and experienced an unprecedented transparency from the companies. The language barrier has noticeably decreased, and Japan seems to be opening up more, according to our impression. Read below for some specific excerpts from our journey.

We spent the first 24 hours in the industrial region of Funabashi, northeast of central Tokyo. Right after our arrival, we tested the quality of a budget sushi chain, listed on the stock exchange and part of our Fish & Seafood universe. Ten days later, we learned from a financial analyst covering the chain that we had visited an old store concept. In the urban zone, there were two newly designed stores just around the corner, but both had queues that would have stolen 60 valuable minutes of our time. We caught a brief glimpse and saw the difference in terms of digitalization. The conveyor belt is now displayed as a cartoon on a large screen at each table, while the actual conveyor belt runs concealed. The chain had to deal with a prank that went viral on social media. Boys had licked food and put it back on the conveyor belt. There are indeed all sorts of risks when it comes to investing…

Without licking the sashimi, we continued the next day with a tour of a cold storage warehouse. The volume of food handled here is equivalent to about 600 million meals per year. It would be enough to serve 15 dishes per year to each person in the Tokyo metropolitan area (over 40 million inhabitants). In the rooms where the temperature was -23 degrees Celsius, we got a taste of the impending winter in Europe. Later, we visited a factory facility completed in 2014 by the same company, which produces frozen food products. In addition to cold storage logistics, food production is the company's second main business area. Despite Japan's shrinking population, this segment is growing due to the lack of time for cooking.

On the same day, we flew to Matsuyama, where a tour of a tuna farm awaited us in the southwest of Shikoku Island. The bluefin tunas moved nimbly in their enclosure but were hefty. One specimen, about 4 years old and harvested, weighed over 82 kilograms. With a portion size of 150 grams, that's nearly 550 meals. The Japanese mastery of utilizing every part of the fish was evident when we were served the heart of a tuna as a delicacy in a selected restaurant. A side trip to a breeding station was just manageable on the same day. In this facility, small fish are bred from hatching until they reach 5cm in size. Unfortunately, bluefin tunas were not 'in season', but we were able to observe tiny yellowfin mackerels.

Midway through our journey, we found ourselves in the prefecture around Kagoshima, home to the active Sakurajima volcano. Numerous farms are located around the volcano in Kagoshima Bay. We visited the largest operator, who had his cages at six different locations. The wave action, particularly during storms or typhoons, unfortunately does not allow for fully automated feeding in this region. The water stations would be too exposed, giving the Norwegians with their fjords certain advantages. Since sharks regularly swim in the bay, metal cages are used out of necessity. A state-subsidized innovation are new, large copper cages. The advantage of the copper-coated cages is that they attract fewer pathogens, algae, and mussels. This not only improves animal health but also eliminates the need for regular cleaning.

In the south of Kyushu, another active volcano, Kaimon-dake, is located in the region. About 15 kilometers further west, we had the opportunity to visit a land-based shrimp farm equipped with Biofloc technology. Instead of using energy-intensive biofilters to clean the water, natural microorganisms are employed directly among the shrimps. They purify the water and essentially produce feed for the shrimps, creating a partially self-sustaining, circular economy in the ponds. Right next to the shrimp facility is what is probably the most advanced hatchery for marine fish in Japan. Established in 2014, it can produce three million juvenile fish per year. It is part of an integrated value chain for Hamachi, which belongs to the family of yellowtail.

The next day in Miyazaki Prefecture, we scheduled a tour of aquaculture farms in Shibushi Bay. Particularly impressive was their practice of keeping cages about eight meters below the water's surface due to the wave action they have experienced over the years. The range of water temperature is narrower there, as the surface water can warm up to 30 degrees Celsius in the summer. The greater the temperature fluctuations, the more stress is placed on the fish. The farms have been ASC-certified in recent years, as their end products are now also shipped to Europe. The processing facility of the same company processes about 25 tons of fish from their own production each day. Unlike their competitors, they can deliver their fish daily in the desired quantity. Especially in months when no wild catch of that species is available on the market, they achieve good prices. The assurance of a steady supply is valued by restaurants worldwide.

Whenever a short break was needed or hunger struck, we visited large and small supermarkets in search of familiar products. We were particularly surprised by the frozen food section, where the Japanese titles in our investment universe dominated with a diverse selection. The prices in yen were always impressive. The depreciation of the Japanese currency is a blessing for foreign tourists. For the population, budgeting is becoming increasingly tight, but there still seems to be enough money for food. This is evident in the reported figures of the companies.

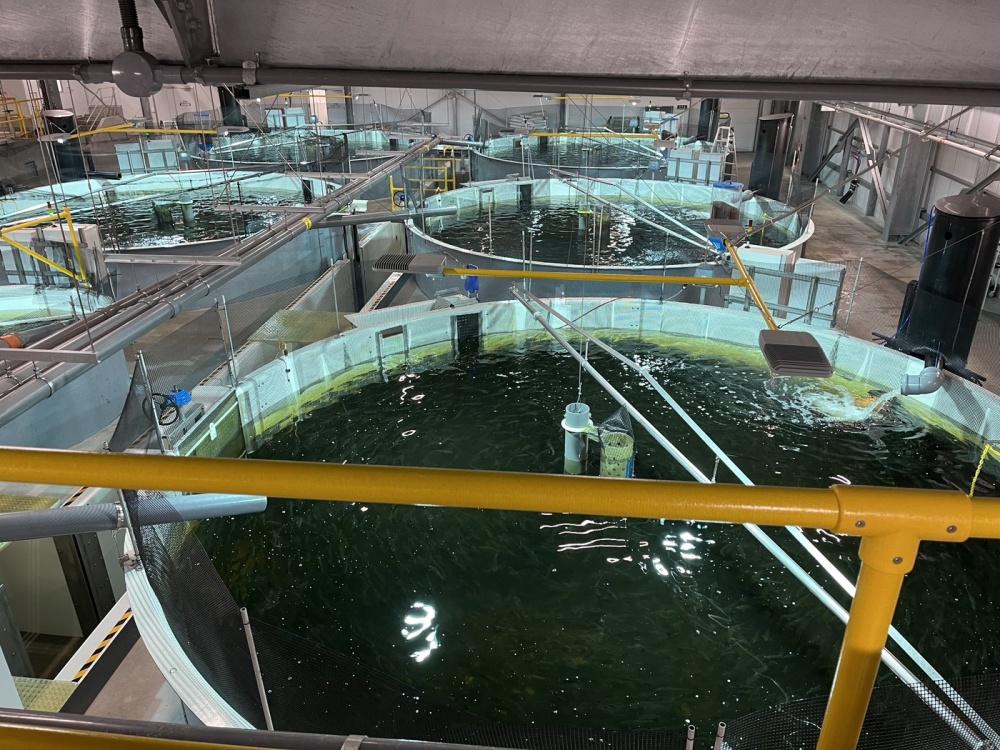

The last few days were spent in Tokyo, where, aside from numerous meetings with investors, analysts, and companies, a visit to a land-based salmon farm was also planned. Just a two-hour drive from the center of Tokyo and in close proximity to Mount Fuji, Norwegians have set up shop. In a huge hall with tanks measuring 18 meters in diameter, Atlantic salmon are expected to reach the Japanese fish markets by 2024. While fingerlings and smolts are already swimming in the breeding station, the final touches are being made to the large modules. The plan is to produce 5,300 tons annually, which equates to over 35 million salmon meals in portion sizes.

Picking a highlight from the trip is difficult. However, what consistently impressed us was the quality of the meals. From affordable noodle soup in a metro station to sushi at a specialist, the flavors always pleasantly surprised us. The Japanese cuisine embodies culture and tradition. It's no wonder that dishes from the Land of the Rising Sun are spreading worldwide. Now, it's just a matter of Japanese aquaculture companies starting to export their quality products abroad. And the trend is moving in the right direction. More on this in our separate blog: 'Wagyu and Kobe beef soon from Japanese waters?'

Comments