1. Chile Report: Salmon Farming

At the beginning of 2019, we took the opportunity to visit salmon farming operations in the Chilean summer.

The end market for locally produced fish and seafood remains small. Land-based aquaculture, with its high investment and production costs, faces a limited customer base for expensive but regional products. Since the pandemic, when money was temporarily loose, many founders and investors have learned this lesson the hard way - worldwide. In the future, the vacancies will only be filled by innovative companies that take things step by step.

In long pond channels using wood materials, the inventors around Alex Dubsky built their second test facility in order to gradually increase production volume. Since 2019, their first breeding cycles have been taking place in a basement in a rural area of the Canton of Zurich. Prior to this, the environmental engineer gained expertise at the University of Kentucky in the USA, a renowned center for biofloc technology. Plans are already in place for the next test facility. This time, it will be located in a former pigsty, where the experience gained from the current facility will be further incorporated. The brownish-colored, nutrient-rich water may seem unappealing to consumers, but it is commonplace in mangrove forests, where shrimp are native.

Biofloc technology relies on a self-regulating microorganism in a closed water system. The bacteria convert the shrimp's feces back into proteins, which in turn serve as feed for the animals. This enables significant savings in feed costs, as between 20-50% less external feed needs to be purchased. Feed is wellknown to be the biggest cost factor in aquaculture, which is why Biofloc technology is so appealing. The biggest risk is changing parameters in the water. Shrimp need oxygen, while the environment must also be right for the bacteria to thrive. Constant monitoring 24 hours a day, 7 days a week, and emergency plans to respond appropriately are therefore key elements of this breeding strategy.

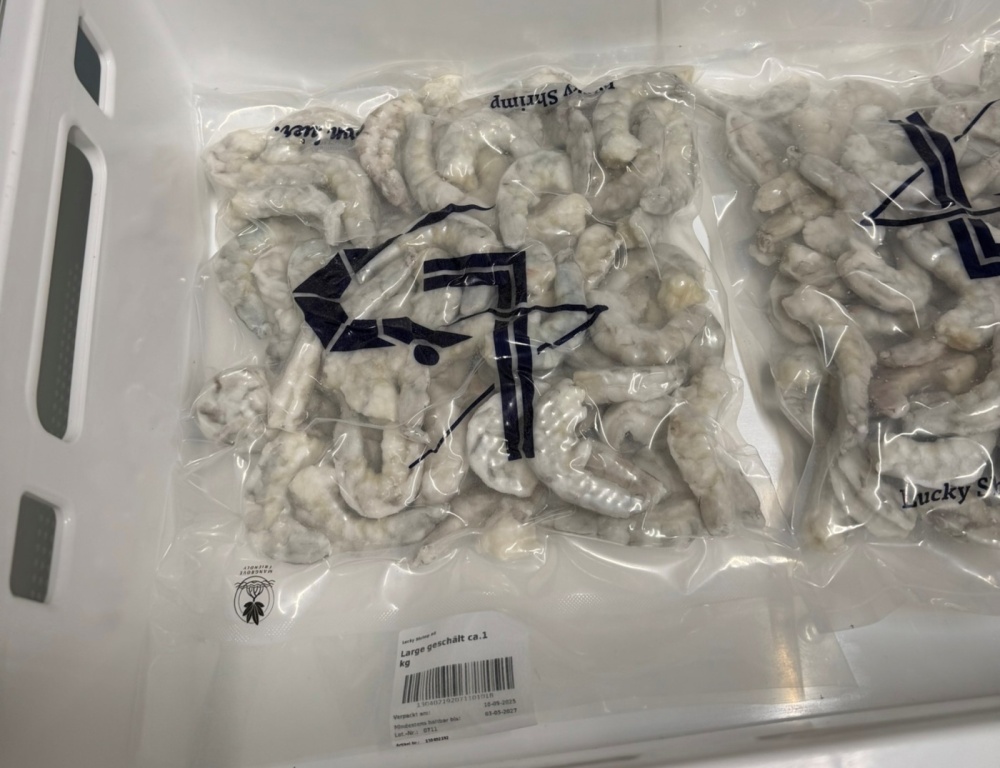

Land-based facilities, which require a significant amount of investment capital, demand the highest possible capital turnover in order to achieve an acceptable return. Accordingly, the (successfully implemented) three-month farming cycle until shrimps are ready-for-sale is essential. Unlike several competitors in Europe who have had to file for bankruptcy in recent years, LuckyShrimp never built an expensive palace used for the grow-out. This results in lower depreciation costs. The company's own plant design also saves on expensive service contracts from third-party providers, but promotes dependence on key individuals.

If land-based aquaculture facilities are to play a role in Switzerland's food security in the future, LuckyShrimp is one of the few projects worthy of support. However, the continuing shortage of space in Switzerland and high labor costs require entrepreneurial flexibility. Regional farmers often cite CO2 emissions from transporting fish from distant countries as a pro argument for their projects. We find this argument unconvincing as long as feed or ingredients also have to be imported from abroad. Advances in the circular economy, for example with insects as a feed ingredient, could remedy this situation. In addition, it should not be forgotten that indoor facilities are more energy-intensive than conventional aquaculture. Switzerland in particular is vulnerable as an electricity importer in winter. But time, values, and resources can bring about positive change in the environment.

„The goal at LuckyShrimp is to be able to compete on price with imported organic shrimp despite producing in Switzerland - and this can only be achieved through consistent efficiency and the company's proprietary system. As a result, the shrimp are already around half the price of comparable Swiss products.“

Alex Dubsky, managing director Lucky Shrimp AG

You can find out more about the company on its website: luckyshrimp.ch

Comments